Pipe leak and pressure testing

Pipe leak and pressure testing is an essential practice in the construction, maintenance, and repair of piping systems. It consists of subjecting pipes to controlled hydrostatic pressures to verify their integrity, strength, and sealing. This procedure is crucial to ensure that pipes comply with the required safety and quality standards, preventing potential leaks or structural failures that could result in material damage or safety risks.

Detecting any leaks

During leak and pressure testing of pipes, the pipes are filled with water or another suitable fluid and subjected to a specific pressure, usually above normal operating pressure. The aim is to detect any leaks, deformation, or faults in the pipe that could compromise its integrity. Our specialized technicians carefully monitor the behavior of the piping during the test, observing pressure variations and visible signs of leaks, such as water dripping or air bubbles.

There are different pressure testing methods, including hydrostatic testing, where the piping is subjected to static pressure for a specified period, and pneumatic testing, which uses compressed air instead of water. The choice of method depends on the characteristics of the piping, the fluid being transported, and the applicable regulatory requirements.

Practical effects

In addition to ensuring the structural integrity of piping, leak and pressure testing of piping has significant practical effects at various stages of the facility lifecycle. For example, during the construction phase, these tests are crucial for identifying and correcting any sealing problems or structural flaws before the system goes into operation. This helps to avoid schedule delays and additional costs associated with repairs or work required after construction is complete.

During the operational phase, pressure testing helps ensure the continued reliability of the system, reducing the risk of leaks that could interrupt fluid supply or cause damage to the facility and the environment. This is especially critical in industries such as petrochemicals and food processing, where even small leaks can result in significant product losses or safety risks for workers.

In addition, pressure testing plays an important role in regulatory compliance, as many standards and codes require piping to be tested regularly to ensure its safety and compliance with applicable engineering standards. This is essential to protect public health and the environment by ensuring that piping systems meet the highest standards of quality and safety.

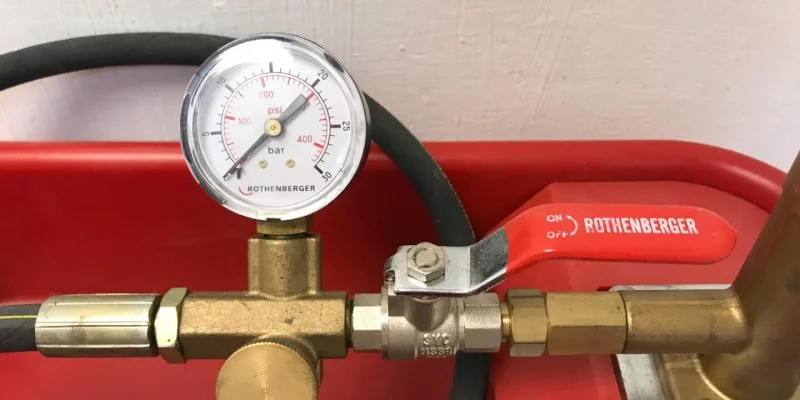

Rothenberger RP30

A common piece of equipment used by SaltOrnamental to perform leak and pressure tests on pipes is the Rothenberger RP30, a compact and robust pressure tester that offers precision and reliability in pressure measurement. With its technology, the Rothenberger RP30 allows pressure tests to be carried out easily and efficiently, providing accurate results that guarantee the safety and quality of the pipes tested.

In addition to ensuring the safety and quality of pipes, pressure testing also plays an important role in certifying the compliance of piping systems in various industries, including petrochemical, shipbuilding, water and sewage systems, among others. The results of the pressure test are documented in detailed reports, which can be used to prove regulatory compliance and the quality of the piping system.

In summary, pipe pressure testing is a fundamental step in the installation, maintenance, and certification of piping systems. It ensures that pipes are in proper working condition, minimizing the risk of leaks, structural failures, and associated damage. Therefore, it is essential to have qualified professionals and appropriate equipment, such as the Rothenberger RP30, to perform these tests effectively and safely.

Learn more about our services here.